Standing on the precipice of retirement after a career in mechanical research and development (R&D), Dieter Hilker clearly recalls the boyhood moment that was a harbinger of things to come.

“When I was 15, I took apart my father’s Volkswagen and made a snow plane,” Hilker said. “I found a couple of bed frames and welded them together at my friend’s farm. I made a propeller at school and brought it home. With a little help from my dad who somehow always supported my crazy ideas, we assembled it and finally got it started – and it actually worked!”

Hilker hit a few trees on that maiden voyage but, no worse for wear, a lifelong passion for mechanical design took root.

On December 31st, Hilker officially retired from Paprima, after a career that saw him come on board in March 1995. Paprima, part of the Canerector family of companies, is a world leader with state-of-the-art offerings of High Pressure Water-Jet Technology mainly for the Pulp and Paper Industry.

Hilker’s professional journey began by studying mechanical engineering technology at Dawson College. Living in the Montreal area as the son of German immigrants, Hilker leveraged his ability to speak German to take a job with a German company in Canada in their R&D division developing diesel engines. He would later move to Germany for seven years, working and touring all over Europe.

Hilker returned to Canada and set out on his own as a freelance consultant. One day he needed a certain piece of equipment which brought him to the door of Paprima owner Roman Caspar. The two like-minded entrepreneurs struck up an immediate connection which eventually led to Caspar offering Hilker a job.

“I told him, ‘No thanks, I’m working for myself,” Hilker said. “But I soon found out that to be a successful entrepreneur you actually had to be good at business, so I decided I better take that job offer after all!”

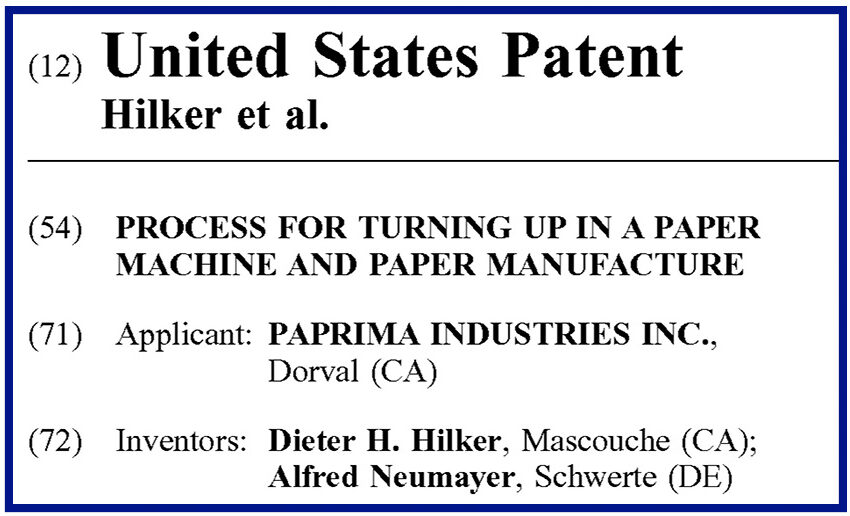

With his new team at Paprima, Hilker was instrumental in developing several key patents that would revolutionize operations for pulp and paper mills and lead to major cost savings.

A paper mill’s profitability depends on keeping the machine running with as little down time as possible. When a paper break causes stoppage, the organization loses approximately $1,000 a minute. Hilker helped to develop Paprima’s patented Water-Jet Turnup Technology that uses high pressure water to cut the paper in such a way that it wraps around the roll neatly from the middle to the outside. This results in a continuously running paper machine.

“By going with our Water-Jet system, there’s no need to throw away much paper from every roll. We’ve saved tons of paper by evolving this inefficient process,” he said.

As Hilker reflects on those early days, he’s brought back to the excitement of traveling around and seeing Paprima technology go from research labs to actual paper machines.

“In those early days, when we were breaking new ground with technology, things didn’t always work as expected on the first try. When it did, we all enjoyed it of course, but we never lost sight of the fact that we had a lot to learn. We simply had to be open to it, believe in it, and persevere. Today we are still learning, and it’s a great personal satisfaction when things work as they should with the first push of a button,” he said.

Part of Paprima’s culture that still stands to this day is a spirit of entrepreneurism that originated directly from Roman Caspar himself. One day Roman came into the office and gleefully announced he had sold two tissue slitters. Cheers went up all through the office and then someone from the team asked a pressing question.

“What’s a slitter? We had absolutely no idea. Roman told us, whatever it is we better figure it out!” Hilker said.

The team would quickly learn about these machines that cut paper into four to six-metre-wide strips. And within three months, they had a working prototype.

“That’s just the kind of team we’ve always had,” Hilker said. “We can always rely on each other to do what it takes to get the job done.”

Matt Warden, Canerector’s Co-President, believes Hilker is a shining example of how Canerector’s people are the most important driver of the company’s success.

“Dieter has made incredible contributions to Paprima’s work and culture and while he will be missed, his legacy lives on. Hearty congratulations to Dieter on his retirement from the entire Canerector team,” Warden said.

Alain Verville, Paprima’s President, shared a touching tribute with these words:

“Two years ago, Dieter announced his retirement, but I couldn’t fathom letting go of his wealth of knowledge. I pleaded with him to stay part-time, and here we are, two years later, still reluctant to bid farewell. Dieter, a dependable force, has always been there for us—whether flying across the globe at a moment’s notice for a startup or conducting pressure cutting tests in the shop. We’ve only scratched the surface of documenting the treasure trove in his mind. On his final days with us, he dedicated himself to helping design a new head cleaning process, displaying his passion until the last minutes. Dieter, your legacy is etched in every project; the impact of your dedication will resonate in our endeavors. Cheers to a well-earned retirement and the lasting imprint you’ve left on our hearts and in the company’s history.”

In his retirement letter, Hilker spoke about the great joy in watching Paprima evolve throughout his time there. “I’ve had the honour and pleasure of working with- and learning from some amazing coworkers and friends both here and abroad, all the while watching Paprima move into its new home in Dorval, join the Canerector family, and continue to grow into a company that has something very special – a worldwide reputation.”

Hilker said he most looking forward to spending more time with his wife and family and using his well-honed skills to fixing things around the house.

“Trust me, I’ve got a long To Do list from my wife!”

When that list is finally tackled, is there a chance the natural-born inventor might have a modern take on the snow plane in the near future?

“Well right now, I’ll just be happy if I can get my garage door to work properly,” he said. “But yeah, I occasionally picture those days when it was so much fun making dune buggies and things like that… so, we’ll see.”