Any fan of the classic story The Wizard of Oz will be familiar with the significance of Dorothy’s ruby slippers. They were the key to returning home and were with her the whole time, but she didn’t realize it. Essentially, they were hidden in plain sight.

The same can be said for the wide variety of products that come out of Gamma Foundries, a proud member of the Canerector family. Founded in 1959 and based out of Richmond Hill, Ontario, Gamma Foundries produces aluminum and copper base alloys, non-ferrous sand casting, and stainless-steel castings from ounces to 3500 lbs.

It’s almost a certainty that everyone has, at one time or another, laid eyes on the brilliant craftsmanship of Gamma Foundries without realizing it. That’s because Gamma products are almost everywhere – from water meters found in residential basements to public displays. Anyone who has ever watched the spectacular water fountains at Niagara Falls and Mont Tremblant (near the Gondola), for example, witnessed a work of art made possible by the nozzles produced by Gamma.

“We did that!” said Vishal Sharma, Manager of Engineering at Gamma. “Nobody can tell by looking at it, but the work we do at Gamma Foundries makes those beautiful fountains possible.”

Knowing their work has a real-world impact is a huge draw for Gamma’s employees.

Improving drinking water

Perhaps nowhere is this more evident than in the work they do to improve the quality and access to drinking water. Whether it’s right here at home or around the globe, Gamma has leveraged its expertise to make drinking water safer and more accessible where others have fallen short.

“We’ve built a name for ourselves in quality, responsiveness, and technical capabilities. Nothing less than the best will do,” Sharma said.

A great example of what makes Gamma shine can be found a little further from home. Gamma was called in to help salvage a complex water drilling project overseas that had been going on for years without success. Despite a large investment, the previous team’s work had ended up on the scrap heap. Gamma was called in to develop a workable solution.

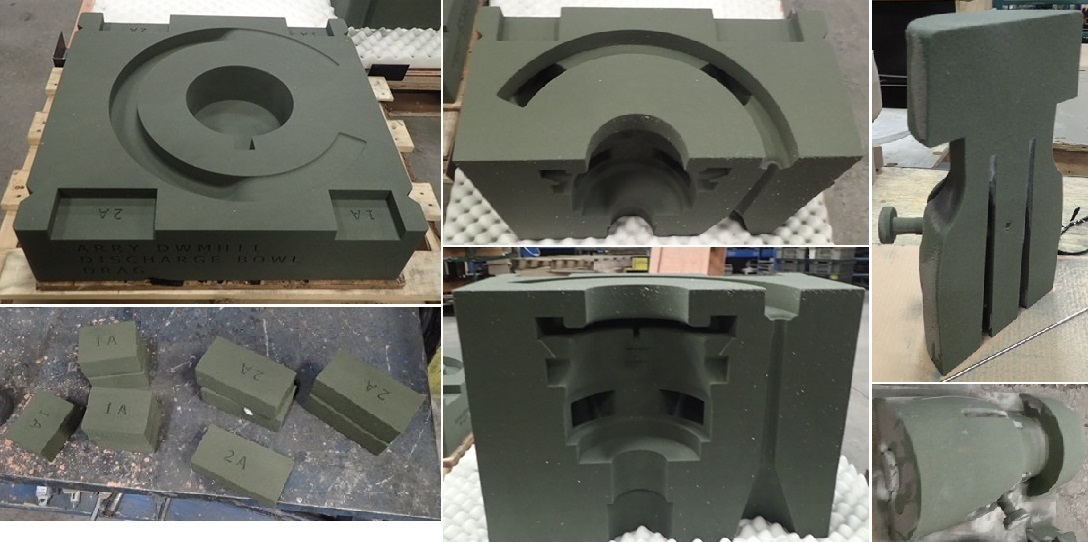

“That was where we started using 3D scanning and 3D printing technology,” Sharma explained. “Using 3D scanning, we discovered one of the parts was faulty – the holes were off center. Not surprising, given the part was 100 years old!”

Gamma then used 3D printing technology to sand-cast a new mould, and with that, they successfully accessed the water source, 300 meters below the desert surface.

“We were all extremely proud of our success on that one. I’d say that’s the exact moment Vishal fell in love with foundry,” Peter Gyozo, a Foundry Technician at Gamma, shared with a smile. Sharma chimed in, “Several dignitaries were invited for the official celebration, it was quite a big deal.”

Producing literal works of art

Gamma Foundries’ expertise in highly detailed and technical production is also called upon to bring items of cultural significance to life. Whether it’s refurbishing an 1800s train, or creating larger-than-life badges of honour, Gamma is up for the task.

One badge can be seen hanging in the OPP Museum in Orillia, Ontario, commissioned to commemorate a fallen officer. “There’s an important societal connection that goes with the police badge. Kids grow up dreaming about them. It’s a tremendous honour that Gamma was trusted to produce one as significant as this,” Gyozo said.

The sense of honour that comes with replicating badges occurred once again when Gamma produced a replica of a service badge for a retiring Fire Chief. While not readily in public view, this one is still hung in a special place of honour.

“He hung it above his basement bar,” Gyozo said. “That’s a special one for us too.”

Whether it’s items large or small, deep in the earth or deep in your heart, Gamma’s General Manager Ryan Bishop, believes there is one common denominator that plays a huge role in everything they do.

“Gamma’s secret sauce is the engineering team, with the focus on team,” he said. “Each member individually, has incredible talent, but combined, they have overcome, developed and reengineered amazing things, all with a relentless pursuit to customer satisfaction!”

The proof-in-the-pudding for the success of this approach can be found in a recent quote from one of Gamma’s top customers. “Gamma continues to supply 90% of our parts due to the fantastic engineering services they provide.”

So, while the products Gamma Foundries manufactures may be hidden in plain sight, the positive impact they have on the world around us remains proudly on display for the world to see.